Standard general arrangement drawings, and piping and instrumentation diagrams, serve a purpose, but they are not ideal records for as-built project documentation. 3D reality capture offers a better, more-useful tool for owners.

Over the course of a few weeks, the normal project execution process has shifted, as many companies set new guidelines limiting interpersonal contact during the COVID-19 pandemic. "Normal" has vanished and may not return, at least not in the near term. The ability to bring various subject matter experts, vendors, contractors, and safety specialists onsite during a project's conceptual and planning phases has become difficult due to social-distancing requirements. Further complicating matters, some companies are reluctant to let employees travel at all, making site visits impossible.

Social distancing brings the challenge of sharing necessary project information with disparate groups across the globe in a simple format. Pictures are nice, but often do not provide the needed vantage point and are typically useless for measuring. 2D drawings can be hard to locate, harder to decipher, many times are not up to date, and often lead to more confusion than clarity.

|

|

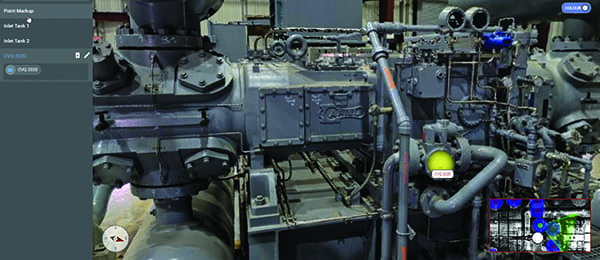

1. 3D reality capture can produce detailed and interactive views in point-cloud, photo-realistic, or solid-model formats. The compressor shown here is one example of what can be displayed on a computer or web-enabled mobile device. Courtesy: AsBuilt |

Imagine a world without a need for 2D drawings, in which all needed information was available ahead of time, in an accurate and easy-to-use format. This world can be created with 3D reality capture and delivered in point-cloud, photo-realistic (Figure 1), or solid-model formats. Modern equipment and advanced workflows have provided a means to create these virtual worlds in a cost-effective and timely manner. Every major retrofit project should start with reality capture and leverage trusted data through each stage of project execution. At project conclusion, the final as-built documentation should be captured in 3D, as its uses extend far beyond simple diagrams.

3D Reality Capture

3D reality capture has been around for decades, but it has not been widely adopted due to factors such as availability, cost, delivery timelines, and a lack of understanding of the dynamic impact it can have in all phases of a retrofit project. Those who tried 3D reality capture in its early days often received a point-cloud deliverable, which was not easily applied to common design applications. A lack of support from the 3D reality capture service provider left many early attempts to be viewed as failures.

Today's top 3D reality capture suppliers understand the need for post-capture technical support for their clients. By supporting solid modeling of the point cloud, simulations, clash detection, overlays, drawings, software training, and workflow implementation, the client is equipped to focus on the project at hand and not saddled with self-education.

What does the workflow look like? It all starts with a conversation. Making certain the 3D reality capture provider is thoroughly informed is the first step in project risk reduction. Assessing project goals, determining which data points are most important, and prioritizing goals should be a part of this conversation. Capturing and delivering valuable data initially allows for the exploration of concepts, scope development, and thorough requests for quotation. Secondly, site, demo, lifting, safety, laydown, installation, and operation planning can be easily visualized and simulated as long as the proper areas and equipment are captured.

Successful Outcomes

Once goals are understood, the 3D reality capture team can get to work. Some of the steps required and benefits provided by reality capture follow.

|

|

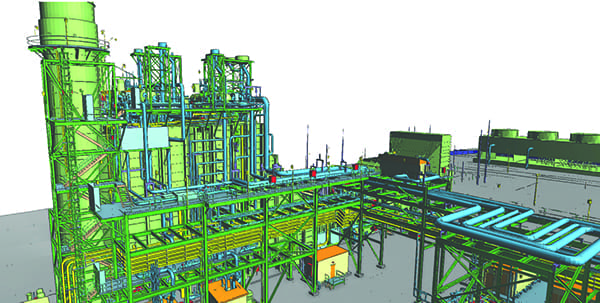

2. 3D models can be constructed to represent a complete facility, with the ability to zoom in to specific areas and calculate minute dimensions, if desired. Courtesy: AsBuilt |

The Capture. Why send a team of engineers to a project site to "measure up" the situation? This has been common practice for many years, yet, this typically results in missed information, inaccurate dimensions, and a costly return trip. A well-trained scan tech and one scanner can capture more information in one day than a team of engineers could possibly capture in months, maybe years. The most exciting factors being: scan data is true, trusted, and can be immediately applied with the utmost confidence (Figure 2).

Post-Processing. Capture data is post-processed to stitch the multiple scans (sometimes more than 3,000) into one point cloud. Post-processing develops not only the point cloud, but also the 360-degree photorealistic views, which are very helpful in the project execution process. Post-processed data can be uploaded to an enterprise-level cloud collaboration system, allowing users to start working with the photorealistic views over a web browser in just a matter of days. Meanwhile, point-cloud data is being transformed into solid models for use by engineering and design teams.

Collaboration. Discrete logins to the virtual world can be distributed quickly so teams can begin collaborating and having intelligent discussions while viewing the accurate "as-is" condition instead of the "as-built" from many years past. Simple to very complex measurements–including pipe diameters–can be extracted from the data using a web browser. Real-time markups and annotations can be added to views, which then become searchable and easily located for peer review.

Models of new equipment planned for the environment can be easily located and placed in photorealistic views. This allows users to see how everything fits within the context of the plant. The design can be shared with operations and maintenance personnel to explore not only physical clashes with existing equipment, but also the typically unforeseen clashes between new installations and existing maintenance and operations workflows. Those issues can be resolved virtually in a format everyone understands before they become more-costly rework in the field.

Turbocharge Design Teams. Providing accurate as-built models of subject work areas allows design and engineering teams to begin working immediately, rather than confirming old 2D drawings or struggling with field measurements. Going forward, engineers, designers, and project managers will need scan data and accurate 3D models to limit site visits and large group interactions. Project direction can be determined early and teams can focus more intensely on solutions, as reality capture makes the historically unknown, known.

Empower Bidders. Reality capture allows bidders to work remotely, thus reducing risk exposure by minimizing the number of people coming onsite for bidding purposes. Bid meetings can be conducted virtually, and the virtual plant world can be utilized to visually describe the project being proposed. Site walkdowns can be conducted virtually using photorealistic imagines, questions can be answered in real time with the entire group able to hear both the question and the answer. Virtual meetings can be recorded and shared with all bidders, even ones that were not able to attend the meeting. Real-time measurements can be taken during virtual walkdowns from the comfort of an office.

Cloud-based logins can be shared with bidders, allowing them to explore the virtual world during their bid preparation phase. Bidders can utilize the platform to reduce the workload generated by bidder inquiries, most of which can be answered through exploration of the virtual world.

Supercharge Installation Teams. Information can be conveyed more accurately in the office using the virtual world where safety gear such as hearing protection or respirators are not required, and where attention is not divided between conversation and avoiding site safety hazards. 3D-installation planning is more efficient and transfers substantially more information than traditional walkdowns and 2D information.

Contractors can utilize the reality capture tools during construction to more accurately plan their tasks day by day. The 3D tools aid in project execution, allowing the simulation or visualization of critical tasks, which can then be communicated to the team. Construction verification scans can be performed at any point in the project, ensuring the work is adhering to specification, thus minimizing rework and costly delays.

Project Wrap-Up and Handoff. 3D scanning upon project completion delivers as-built conditions for recordkeeping. Why rely on field-generated redlines that may or may not make it back to engineering groups for model/drawing updates? Scan the finished project, compare it to the 3D design model, and correct the design model to match reality. Generate required 2D drawings from the corrected model.

3D scanning and model data can be warehoused in an enterprise-level system that allows search recall so that other project managers can access the data if they are working in the same area in the future. The data can be utilized for simulations; tours; and as documentation for authorities having jurisdiction, insurance inspectors, and facility safety reviews.

3D scanning and model data can be taken to the next level by adding intelligence to the data and utilizing it as a visual search engine for engineering, maintenance, and even real-time or historical operational data. Access can be given to maintenance planners so they can take screenshots of areas with markups for inclusion in work orders. Trainers and safety professionals can access the data for training, site orientation, and preplanning.

Abundant Benefits Make Reality Capture Worthwhile

Adopting 3D reality capture technology is right for teams, right now. Among the numerous reasons to adopt 3D reality capture into project workflows are:

- ■ It reduces costs.

- ■ It improves schedules.

- ■ It minimizes risks.

- ■ It allows collaboration across multiple locations.

Companies can start with a small project and scale up as paybacks are proven. It is recommended that a full-service reality capture provider with a strong engineering background be selected–one that understands proposed projects from a technical perspective and can provide a framework for developing new workflows. Implementing new technology such as 3D reality capture will lead an organization into the future and make a substantial positive impact on a team's productivity. It's already 2020, why wait any longer to join others in the 3D revolution? ■

–Cale Collier is executive vice president of AsBuilt, an industry-focused engineering and intellectual services provider (www.asbuilt3d.com).