Reality capture uses laser scanning hardware to record the as-built conditions of any environment in a series of scans. These scans, once stitched together, create a holistic picture of structures, equipment, and clearances. Optimizing designs, reducing costs, and improving safety are all improved greatly through the accuracy and detail of 3-D modeling and simulation.

Modern power generation plants have to be able to respond to changing system load requirements by cycling. The stresses this puts on equipment shortens component life expectancies, increasing capital and maintenance costs as well as requiring additional maintenance and repair activities.

These increased maintenance cycles mean more labor hours must be dedicated to maintenance tasks, which increases the associated risks of injury that accompanies them. The Electric Power Research Institute reports that about 45% of injuries in the electric power generation and distribution sector come from overexertion in body motion. On-the-job injuries often result from tasks where the process or the equipment is sub-optimal in design, which leads to awkward motions or poses unnecessary risks of a muscle injury or repetitive motion strain.

As regulations become more stringent, insurance premiums increase, and media scrutiny heightens, it is more important than ever to improve designs and processes to reduce safety risks, reduce on-site injuries, and protect production. Critical or life-threatening injuries are often the focus of safety concerns in the media, but it is the more than 10,000 Occupational Safety and Health Administration-reported minor injuries (sprains, strains, tears, and the like) each year that most hurt production and increase insurance rates.

Injuries and accidents that come down to process and equipment design are avoidable in the same way that unexpected component failure is avoidable–by closely examining the process in place, understanding the situations, and mitigating risks that lead to exertion injuries and accidents. Simulation of equipment operations, processes, and maintenance cycles in 3-D allows close examination of the various scenarios and conditions that may be problematic, which helps plant management pinpoint potentially dangerous situations. New designs can be thoroughly vetted using 3-D simulation before one component is fabricated.

Creating a Digital Twin of Any Environment to Simulate Operations

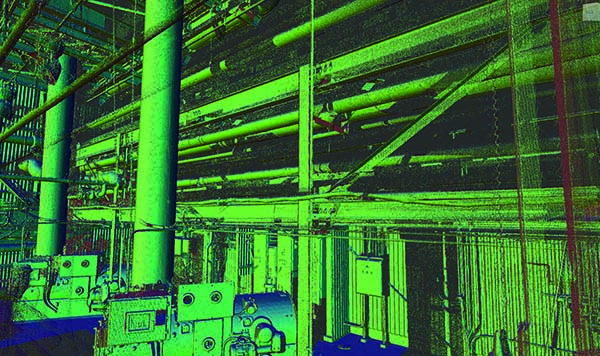

The process of reality capture using 3-D laser scanners has been around for a number of years. As technology has improved, laser scanning has become a practical choice for projects of all sizes. Reality capture uses laser scanning hardware to record the as-built conditions of any environment in a series of scans. These scans, once stitched together, create a holistic picture of structures, equipment, and clearances (Figure 1). Combined with 3-D modeling, 3-D scanning is a powerful tool for simulation. 3-D scanning and modeling provide a natural 3-D perspective, or digital twin, that can be viewed or manipulated on a computer or tablet.

|

|

1. Reality capture using 3-D laser scanners creates a holistic image of structures and equipment. Courtesy: Acensium |

Though many engineers are acquainted with digital 3-D designs for new equipment, the overall environment is typically superimposed on traditional 2-D facility diagrams that leave out key aspects of the facility. There are often small details that can hinder the ability to move or install large components, or that could pose safety risks during the routine operation of equipment.

Cable runs, inspection hatches, and other items not fully realized in 2-D can be easily ascertained and accounted for in 3-D. This ensures that the 3-D digital twin created by laser scanning and enhanced with 3-D modeling simulates equipment, processes, and maintenance cycles accurately and visually, allowing project stakeholders to determine efficiency optimizations or safety risks.

Collaboration and Simulation Drive Risk Reduction and Cost Savings

On dozens of projects working with Southern Company and Duke Energy–consulting on the design and installation of new or upgraded equipment–Acensium has seen the value of a team approach on projects. Collaboration creates success. If leaders want projects to be successful, they need to bring in stakeholders from all levels of plant operations and management. Getting input from all perspectives helps ensure both universal buy-in and a clear vision of the effects of any project on plant operations.

To achieve this, an internal core stakeholder group must be assembled. Include representatives from all levels of responsibility; for example, successful facilities often include engineering, maintenance, operations, and plant management representatives. With all project decisions and scope adjustments, this team, comprised of all possible perspectives, is well-equipped to work through every possible scenario and solution. This process ensures that all plant stakeholders have an influence on changes and all perceivable outcomes are considered.

Simulation of equipment operation and maintenance processes in a digital environment allows the whole stakeholder team to understand what the process entails. The combination of animation and 3-D models make it easier for everyone to quickly understand process steps or equipment design elements, and determine possible issues or difficulties. Animations are typically programmed for better visual understanding after a simulation is completed.

Simulation is the process of modeling the steps of a project or the behavior of a certain object. In the simulation, the operation of the equipment itself, and the operations or maintenance process steps, can be recreated to maximize safety considerations and reduce risk. Simulation in 3-D allows dozens of scenarios or options to be played out, even rare or uncommon situations. This allows the stakeholder team to minimize risk and project cost while finding optimal solutions.

As an example of how simulation and collaboration can reduce safety risks, consider the plant team that identified small changes in the height of inspection hatches and incorporated the use of counterweights to significantly reduced the likelihood of injury-causing accidents and repetitive motion injuries. This was accomplished by having perspectives from throughout the plant as part of the stakeholders' group that analyzed and simulated all new equipment designs and retrofit projects.

3-D scanning and analysis were also a key part of optimizing the performance of a loading crane at a major power producer in the southeastern U.S. Designed to operate at 1,500 tons per hour, unexpected maintenance requirements were driving up costs. Through 3-D scanning and close analysis with the plant team, the issue was determined to be an inefficient angle of operation during one portion of the crane's workload, which was causing undue stress on components. Once 3-D scanning exposed the issue, a number of solutions were readily identifiable.

|

|

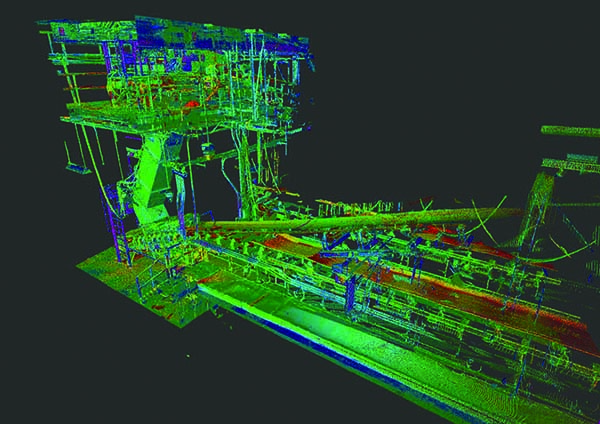

2. 3-D scanning can play a key role in planning and executing retrofit projects. Courtesy: Acensium |

3-D scanning and simulation can play a key part in the planning, execution, and management of any complex retrofit or upgrade (Figure 2). The simulation of demolition and installation steps allows insight into possible difficulties or safety risks at each phase. 3-D scanning during the demolition and installation phases allows up-to-date monitoring of progress and phase completion that gives the project manager the ability to catch mistakes before they compound into more costly issues.

Simulation Consistently Delivers Safety and Efficiency Improvements

Acensium has taken part in more than 1,000 retrofits to existing transfer points, and the design and installation of completely new, custom components in power generation and manufacturing facilities for Southern Company, Duke Energy, and Georgia Pacific. In this time, scanning millions of cubic feet into trillions of data points, 3-D scanning and simulation have consistently provided valuable insight to stakeholders who want to optimize designs and minimize risk.

Using reality capture to have a 100% accurate representation of the environment before, during, and after project implementation is becoming a standard for plant engineers. It has become common knowledge that this technique can allow accurate as-built drawings to be delivered both quickly and cost-effectively. Taking that a step further to using simulation for design and process optimization is simply the natural progression. Optimizing the operations and maintenance process for a new equipment design is often just as important as optimizing the functionality of the equipment itself when considering long-term costs.

Optimizing designs, reducing costs, and improving safety are all critical tasks that the accuracy and detail of reality capture improve exponentially. With scanning, decision-makers have better starting information before planning begins, which means engineers can design equipment with every consideration in mind. Modeling and simulation allow stakeholders to see, for example, that maintenance on a new equipment design could pose serious safety risks without extra clearance. Catching something like that early means saving significant costs in downtime and rework later on.

Making scanning a part of every process review, upgrade, retrofit, or new equipment installation ensures managers always have the data needed to make the best decisions and engineer the best designs. ■

–Cale Collier is vice president of Scan and Model Services at Acensium LLC, an industry-focused engineering and intellectual services provider. Acensium delivers 3-D scanning and modeling, consulting, and operations and engineering support for the execution of construction and retrofit projects (www.acensium.com).